Blast cleaning services in Boston

Here at A.I.A. Shot Blasting Ltd, we offer reasonably priced sho tblasting services to domestic, commercial and industrial clients across Boston and Lincolnshire. Call us now for more details.

Call us now

Shot Blasting services

What is shot blasting?

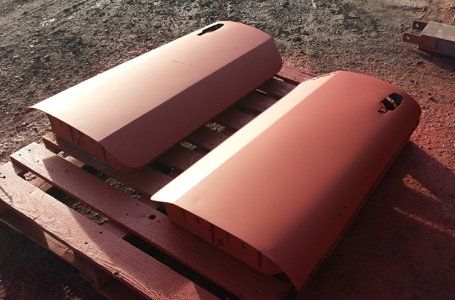

Shot Blasting is the operation of propelling a stream of abrasive material against a metal substrate to remove corrosion, contaminants and to roughen a surface. The process uses controlled pressure depending on the size/delicacy of the part. Parts which have been blasted should then be coated. Primer can be applied to inhibit further corrosion. Items can then be powder coated or airless sprayed depending on customer preference.

How large an area can we shot blast?

Our largest shotblasting

room measures 60ft x 26ft x 16ft High. That’s big enough for most parts.

Don't worry we can handle small parts too.

Blast cleaning for all surfaces

Our mechanical methods ensure that your items are well prepared to ensure good adhesion of powder and wet paint coatings.

Highly experienced

With many years of experience in blast cleaning processes, we have purpose-built facilities for shotblasting. We use of range of different media such as steel grit and copper slag.

We also offer glass bead peening

for stainless steel fabrications.